In the vast world of hardware and fasteners, screws come in a variety of shapes and sizes to cater to different needs. One particular type that has gained significant attention in recent times is the micro screw. Often associated with miniature electronic devices and delicate machinery, micro screws play a critical role in holding together components with precision and stability. In this article, we will delve into the characteristics, applications, and significance of these tiny yet essential fasteners.

- Understanding Micro Screws:

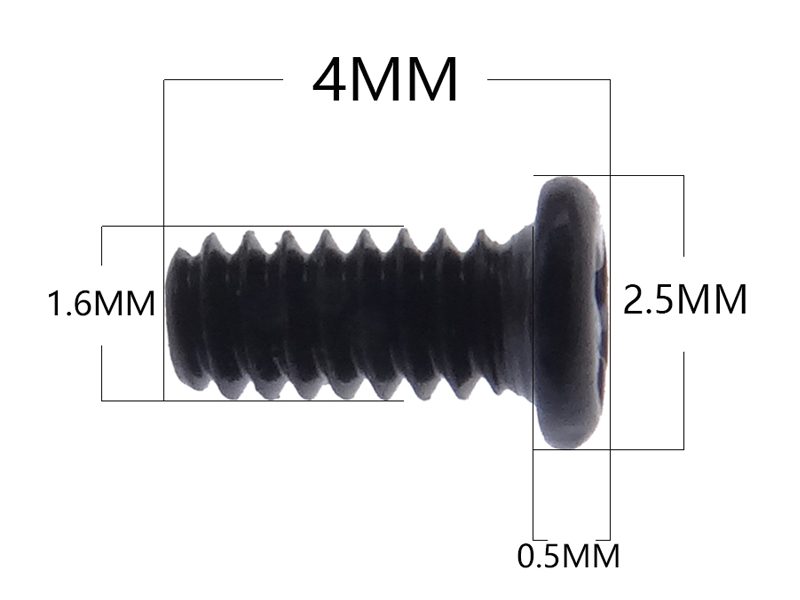

Micro screws are basically screws that have a small diameter and length, usually measuring less than 1.6mm (1/16 inch) in diameter. They possess several unique features that set them apart from regular screws:

- Thread Pitch: Micro screws commonly have a fine thread pitch, enabling them to secure lightweight materials firmly.

- Head Type: They usually feature specialized head types like Phillips, Torx, or flat heads, designed for efficient installation and maximum torque transfer.

- Material: Micro screws are typically made from high-quality materials such as stainless steel or titanium, offering excellent strength and corrosion resistance.

- Applications of Micro Screws:

Micro screws find extensive applications in various industries, including:

- Electronics: These screws are commonly used in small electronic devices such as smartphones, laptops, cameras, and wearables. They securely hold delicate components in place without occupying much space.

- Medical Devices: Micro screws play a vital role in manufacturing medical instruments, implants, and equipment. Their compact size enables surgeons to perform intricate procedures while ensuring durable and reliable connections.

- Jewelry and Watchmaking: High-end jewelry and watches often require micro screws to attach clasps, links, and other components seamlessly.

- Optics and Precision Instruments: Micro screws are crucial in optical devices like microscopes, telescopes, and camera lenses, ensuring alignment and stability.

- Importance of Micro Screws:

Despite their diminutive size, micro screws play a vital role in the functioning and longevity of various products. Their significance can be summarized in the following points:

- Precision Engineering: Micro screws are essential for precise alignment and secure fastening of delicate components, ensuring optimal performance and longevity.

- Miniaturization: As technology advances, electronic devices continue to shrink in size. Micro screws facilitate the miniaturization process, enabling manufacturers to build smaller and lighter products.

- Repair and Maintenance: Micro screws are necessary when it comes to repairing or replacing parts in small devices. Without them, disassembling and reassembling intricate components would be complicated.

Micro screws may be tiny in size, but their impact on modern technology, medical advancements, and precision engineering is substantial. These small yet essential fasteners provide stability, durability, and precision in industries where every millimeter counts. Whether in electronics, medical devices, jewelry, or optics, micro screws play a crucial role in creating compact, innovative, and reliable products that enrich our lives.