HUB inserts are a type of fastener used to secure components onto shafts or axles. They consist of a cylindrical sleeve with an internal taper and one or more slots cut into the sleeve’s length. The insert is placed onto the shaft or axle and then expanded using a specialized tool, causing the sleeve to grip the shaft firmly.

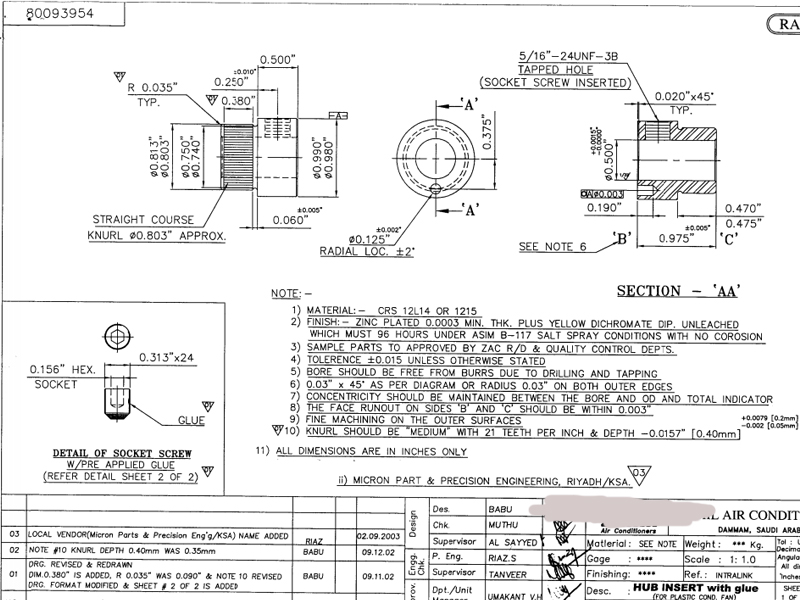

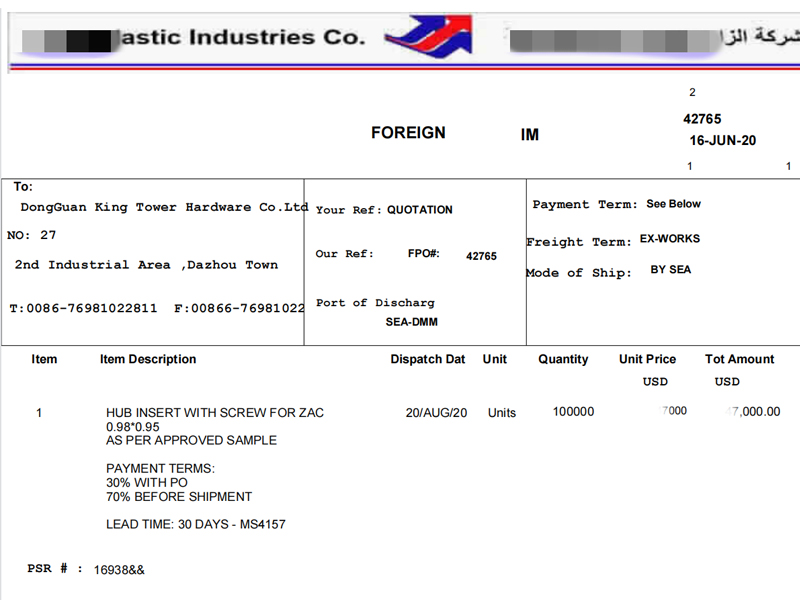

This custom HUB INSERT with socket set screw we supplied to our air conditioner customer in Saudi Arabia. The HUB insert it through CNC machining produced, special straight course knurled in one side, there is a tapped hold for 5/16’’-24UNF-3B socket screw inserted. HUB insert use CRS(Cold Rolled Steel) 12L14 material with zinc plated which must 96 hours under ASIM B-117 salt spray condition with no corrosion. When the customer confirms the sample, the first trial production order quantity is 100,000 sets with a lead time of 4-5 weeks.